Ceramic Techniques & Craft Capability | Qingfa Ceramics

Built on four decades of craftsmanship, Qingfa Ceramics unifies multiple ceramic techniques into comprehensive one-stop ceramic sourcing solutions, simplifying your project from design to mass production with consistent quality.

One-Stop Ceramic Techniques & Craft Capability

Cerâmica Qingfa can handle a wide range of ceramic craft, from basic to advanced, each rigorously tested and validated.

Glaze Finishing

Using high-temperature glaze technology, offering glossy, matte, and other finishes. Ensures a smooth, even surface with rich and long-lasting color.

Decal Decoration

Precise decal technique to perfectly transfer complex patterns onto ceramic surfaces. Patterns are clear with sharp edges, suitable for intricate designs.

Hand-Painted Decoration

Created by skilled artisans, each piece is unique. Ideal for high-end custom and artistic ceramic products.

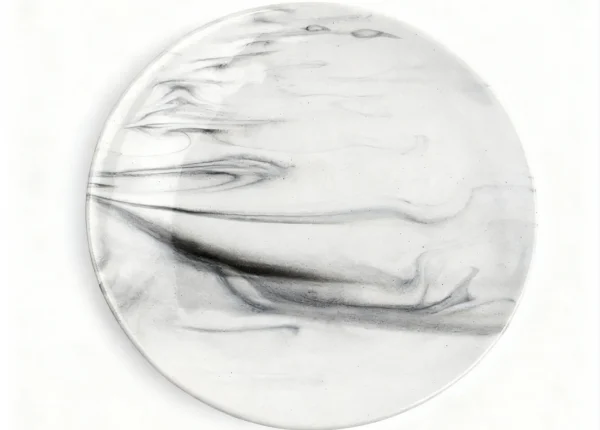

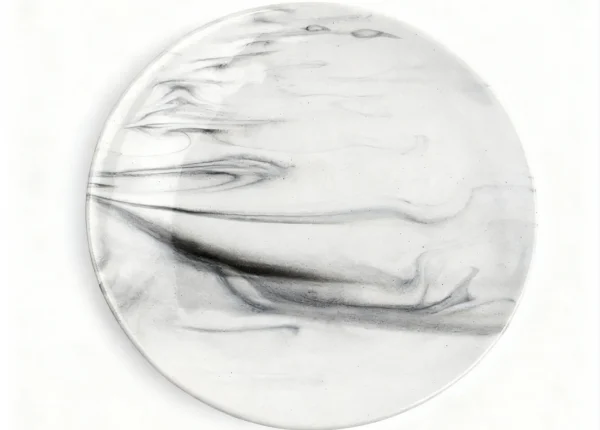

Marble Effect

Imitates natural marble textures with smooth, flowing veins and rich color layers, adding a luxurious touch to ceramic products.

3D

3D ceramic printing technology creates complex three-dimensional forms directly during shaping, resulting in sculptural ceramic pieces with integrated details.

Laser Engraving

High-precision laser engraving achieves micron-level patterns on ceramic surfaces. Patterns are clear, durable, and never wear off.

Piercing / Openwork Craft

Precision piercing technique creates beautiful openwork patterns on ceramics. Complex process with unique visual impact.

Reactive Glaze Effect

Special glazes react at high temperatures to form unique textures and color variations. Each piece is one-of-a-kind.

Gold Rim Decoration

Real or imitation gold application, producing delicate, even gold edges with lasting luster, adding a luxurious feel.

Ink-Splash Effect

Artistic ink-splash technique allows colors to flow and blend naturally, creating unique artistic effects in every piece.

Electroplating / Metallic Coating

Advanced electroplating technology creates metal-like coatings on ceramic surfaces, including silver, titanium, and other effects.

Gravar

Embossing is a surface technique where patterns are formed by pressing molds, producing consistent raised details on ceramic pieces.

Decal Decoration

Precise decal technique to perfectly transfer complex patterns onto ceramic surfaces. Patterns are clear with sharp edges, suitable for intricate designs.

Hand-Painted Decoration

Created by skilled artisans, each piece is unique. Ideal for high-end custom and artistic ceramic products.

Ink-Splash Effect

Artistic ink-splash technique allows colors to flow and blend naturally, creating unique artistic effects in every piece.

Glaze Finishing

Using high-temperature glaze technology, offering glossy, matte, and other finishes. Ensures a smooth, even surface with rich and long-lasting color.

Marble Effect

Imitates natural marble textures with smooth, flowing veins and rich color layers, adding a luxurious touch to ceramic products.

Reactive Glaze Effect

Special glazes react at high temperatures to form unique textures and color variations. Each piece is one-of-a-kind.

3D

3D ceramic printing technology creates complex three-dimensional forms directly during shaping, resulting in sculptural ceramic pieces with integrated details.

Laser Engraving

High-precision laser engraving achieves micron-level patterns on ceramic surfaces. Patterns are clear, durable, and never wear off.

Piercing / Openwork Craft

Precision piercing technique creates beautiful openwork patterns on ceramics. Complex process with unique visual impact.

Gold Rim Decoration

Real or imitation gold application, producing delicate, even gold edges with lasting luster, adding a luxurious feel.

Electroplating / Metallic Coating

Advanced electroplating technology creates metal-like coatings on ceramic surfaces, including silver, titanium, and other effects.

Gravar

Embossing is a surface technique where patterns are formed by pressing molds, producing consistent raised details on ceramic pieces.

Stable Production Process

Qingfa Ceramics has established a complete and efficient production system, ensuring that complex crafts remain consistent across different batches, helping clients minimize mass production risks.

1.Roller Forming

Initial shaping of ceramic bodies using roller forming.

2.Forming

Final shaping and molding of the greenware.

3.Trimming Greenware

Removing excess material and refining shapes.

4.Glazing

Applying glaze for desired surface finish.

5.Loading Kiln

Carefully loading pieces into the kiln for firing.

6.Decaling

Transferring decal patterns onto ceramic surfaces.

7.Decorating Firing

High-temperature firing to fix decorations and glaze.

8.Quality Control

Inspecting final products to ensure consistency and standards.

Why Choose Cerâmica Qingfa?

01

One-Stop Craft Solutions

Handle multiple crafts in a single place, reducing supply chain complexity and simplifying project management.

02

Feasibility Assessment at Development Stage

Evaluate craft feasibility and risk boundaries early in the development process.

03

Stable and Sustainable Mass Production

Ensure long-term, consistent, and reliable product delivery.

04

Long-Term Partnership

Enable more efficient project execution with predictable collaboration.

Cerâmica Qingfa

With 40 years of craft expertise, we offer one-stop solutions for a wide range of ceramic processes. We are dedicated to providing our clients with stable, reliable, and high-quality ceramic manufacturing solutions.

Contacte-nos para um orçamento gratuito

Se tiver dúvidas sobre o produto, precisar de um orçamento personalizado ou quiser saber mais sobre as nossas soluções personalizadas de louça de cerâmica, contacte a Qingfa.

Guangdong, Chaozhou, Fenghsin Street, Tianzhong Village, Xinwei Piece