Strict Ceramics Quality Control at Qingfa

Your Trusted Ceramic PartnerQingfa Ceramics — Ceramics Quality Control & Smart Manufacturing

Since its establishment in 1986, Qingfa Ceramics has committed to delivering high-quality ceramic products that combine traditional craftsmanship with modern innovation. Every product leaving our factory is not only a piece of fine ceramic, but also a promise of reliability and excellence.

Premium Raw Materials & Digital Clay Management

Qingfa Ceramics carefully selects all raw materials from trusted suppliers. Every batch undergoes rigorous laboratory testing for consistency, purity, and performance. With digital clay processing and precise formula control, we ensure that every production batch starts on a solid quality foundation.

Advanced Automation & Precision Production

Qingfa Ceramics integrates modern automation with traditional craftsmanship to ensure precision and uniformity.

● Automated pressing and robotic-assisted casting guarantee exact forming and consistent product quality.

● Fully automated production lines cover all processes from raw material preparation to semi-finished product inspection, enabling continuous production, improved efficiency, and higher pass rates.

Smart Manufacturing System

Qingfa Ceramics has implemented a Smart Factory system with full digital integration, enabling:

1. Intelligent scheduling & visualized production — track production pace, material flow, and task progress in real time.

2. Full process integration — connect R&D, procurement, production, warehouse, sales, and finance to eliminate information silos.

3. Digital collaboration & performance optimization — workers record data directly; departments operate seamlessly.

4. Enhanced quality control & efficiency — early detection of deviations improves yield and consistency.

Three Times Product Full Inspection

Qingfa Ceramics implements a 3 Times Product Full Inspection system, ensuring every product meets our high standards:

1. In-Process Inspection — monitor quality during forming, drying, and firing.

2. Surface & Decoration Inspection — verify glaze, color, and decals meet standards.

3. Final Product Inspection — verify appearance, dimensions, and structural integrity before shipment

Workshops are divided into public and private hygiene zones to prevent cross-contamination and ensure safety.

Smart Inventory & Full Traceability

Qingfa Ceramics uses chip-based inventory management and intelligent production scheduling to monitor:

● Raw materials

● Work-in-progress items

● Finished goods

This allows full traceability from materials to finished products, giving clients confidence that quality is transparent and verifiable.

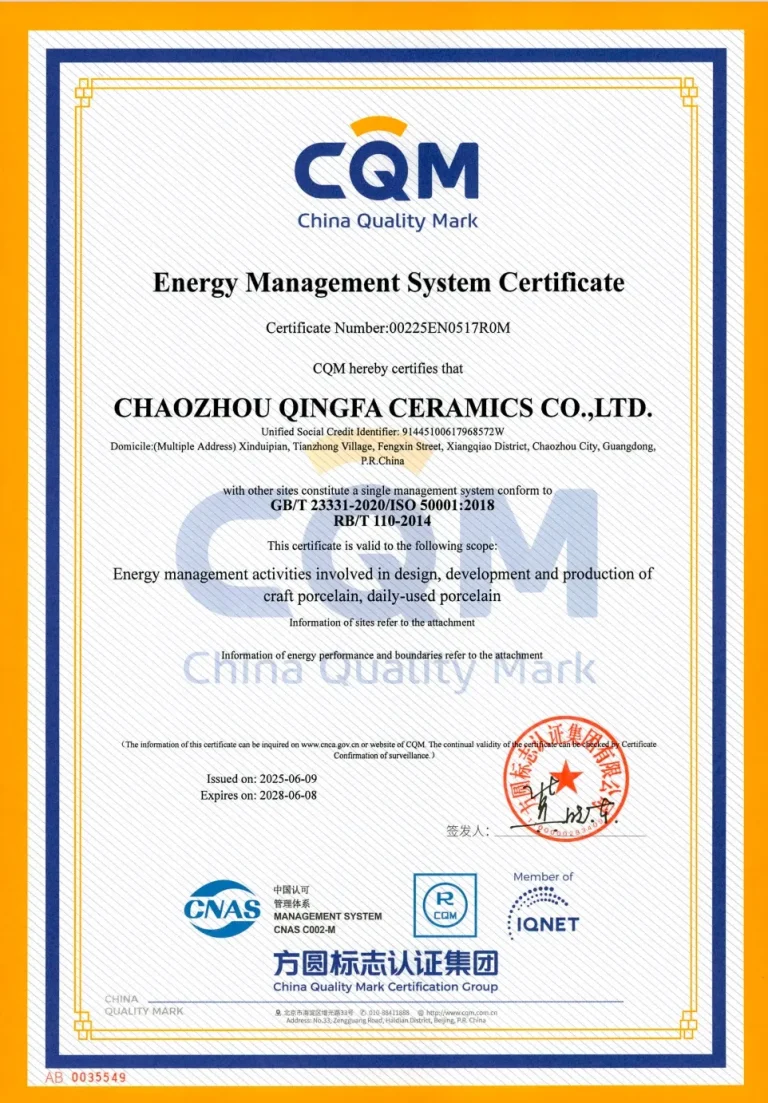

International Standards & Trusted Global Partners

Qingfa Ceramics maintains international certifications including:ISO 9001, ISO 14001, OHSAS 18001, BSCI;Products comply with FDA, LFGB international standards.We proudly supply global brands such as Starbucks, Costco, demonstrating our reliability and long-term commitment.

Clients We Worked With

Our Certifications

Qingfa Ceramics

Qingfa Ceramics is committed to delivering high-quality ceramic products with rigorous standards and meticulous craftsmanship, making us a reliable and trusted partner worldwide.